Top Guidelines Of Pharmaceutical concentration using organic solvent forward

How Passive vsActive Solvent Recovery in Closed-Loop Extraction can Save You Time, Stress, and Money.

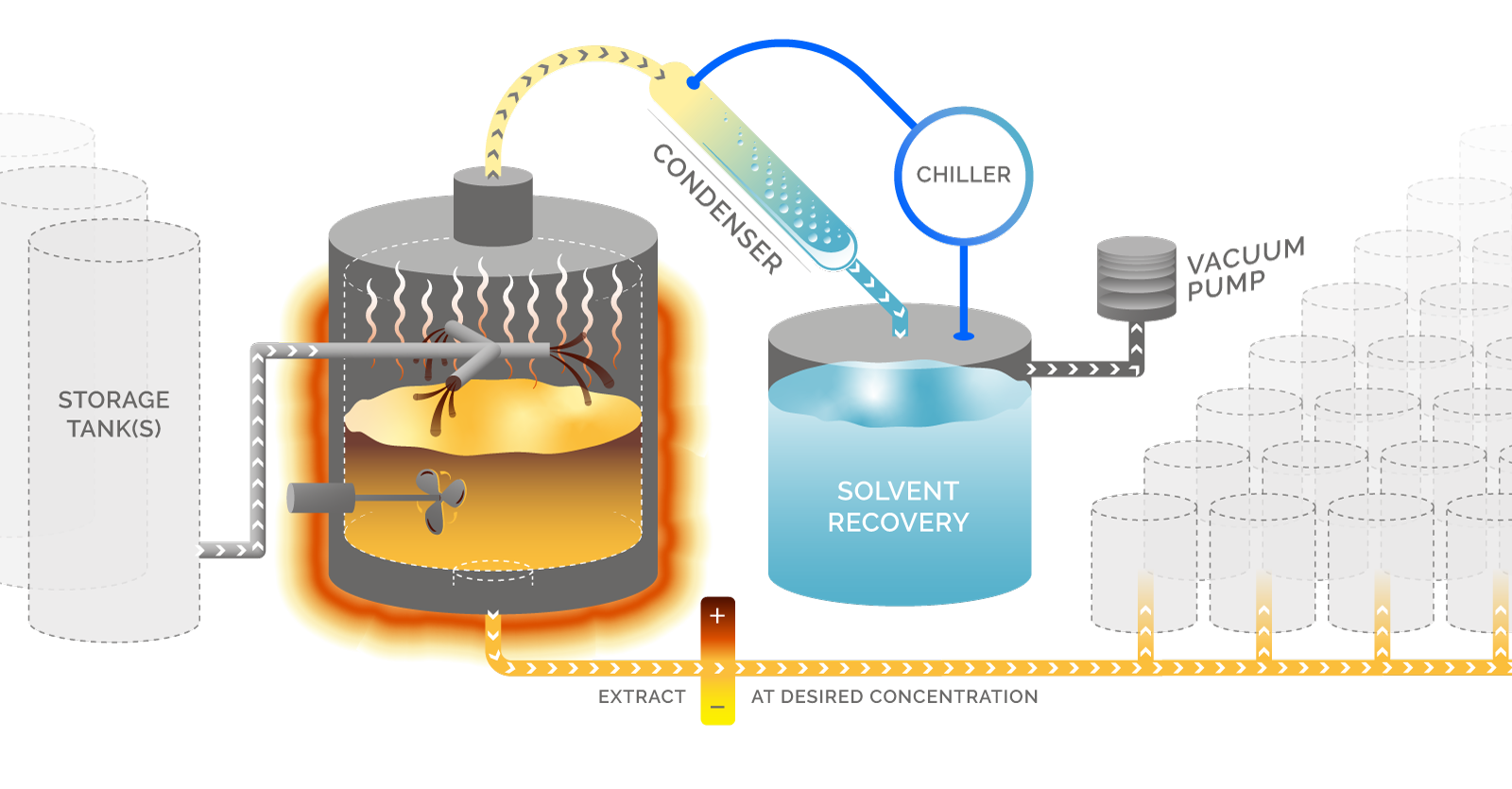

SRS Engineering uses a large range of, and for commercial applications with ideal effectiveness, safety and constant quality. SRS' total line of automated function precision temperature level control in the sludge area, vapor space and thermal oil for ideal performance, security and consistent product quality, making these systems perfect in the most demanding applications in the industry including those involving nitrocellulose Managed by a Microprocessor Distillation rates to 500 GPH 304 stainless-steel construction on all damp surfaces Precision PLC controls Color Touch screen operator interface shows Interlocking safety devices RTD in vapor area, sludge and thermal oil 316 stainless-steel condenser 6 sludge discharge valve Raised base with vent port Assessment platform Ready for single point connectionsOptions Surge ranked for Class 1, Department 1 harmful environments Vacuum systems Car fill Automobile cool Self changing scrapers Solvent tanks Automated transfer pumps systems SRS Engineering Corporation's distill and condense solvents, thinners and cleaners.

Solvent Recovery System From Hongyi youtube.com

Acetone Alcohol Amyl Acetate Butyl Acetate Ethyl Acetate Ethylene Glycol Ethyl Ether Isobutyl Acetate Isopropyl Alcohol Lacquer Diluents Methyl Alcohol (Methanol) Methyl Ethyl Ketone (MEK) Methyl Isobutyl Ketone (MIBK) Methylene Chloride Mineral Spirits Toluene (1-2-3) Toluol (Aromatic Hydrocarbon) Turpentine Gum Xylene (1-2-3) And a lot more All of these can utilize a configuration In the Contamination Prevention Act of 1990, the favored waste reduction alternatives, as specified by Section 6602( b) of the Act, are avoidance and ecologically sound recycling followed by treatment and disposal.

equipment for solvent recovery plant ifsolutions.com

I'm searching for more info aboutPress and print equipmentCoatings and adhesive equipmentCleaning devices and solutionsExpert training, set-up, and guidanceHow did you hear about/find us? * Online SearchWord of Mouth/ReferralSocial MediaArticle online or in publicationAdOther.

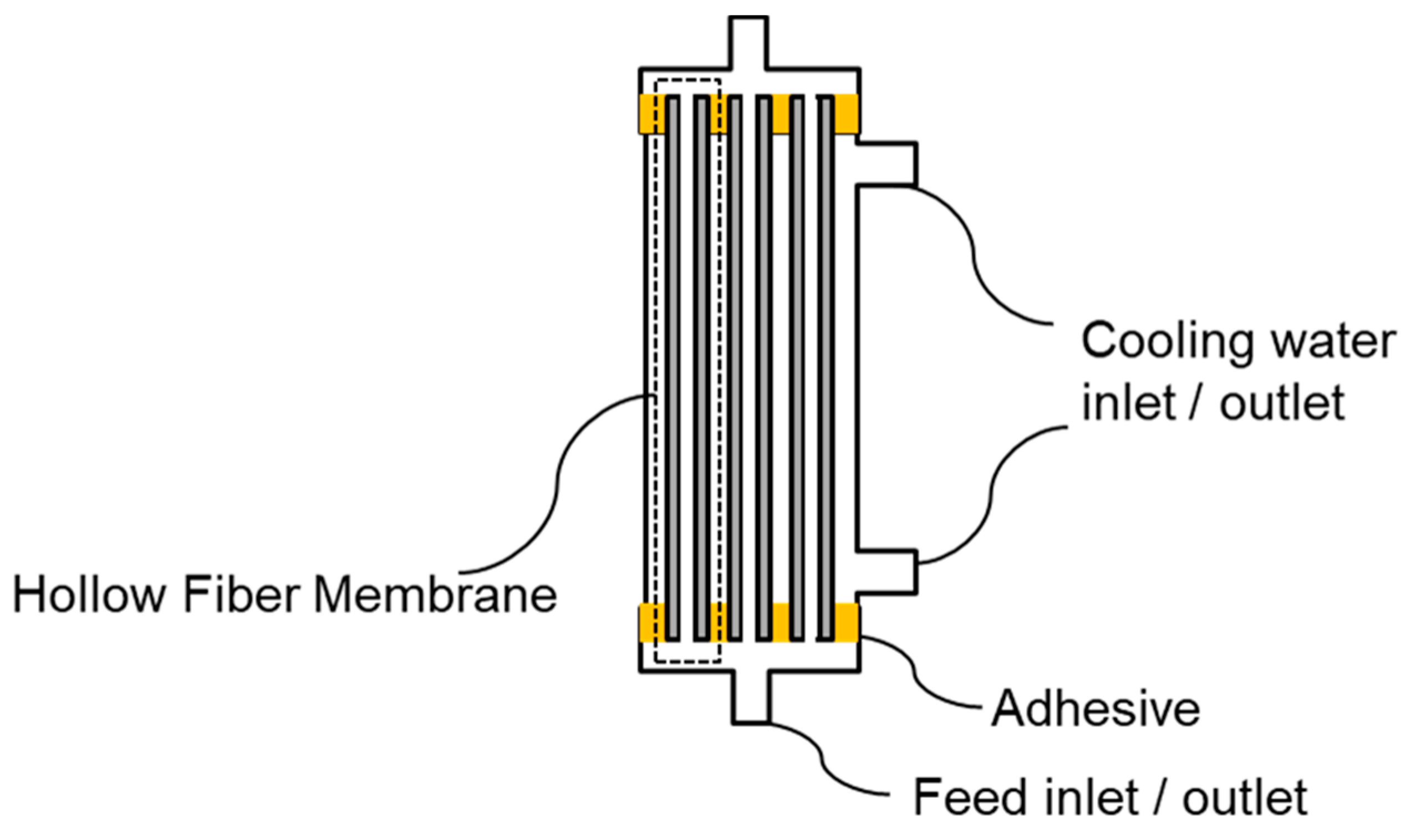

The solvent processing industry, e. g. the printing industry, dry cleaning stores and paint stores, depend on solvents which are vaporised in the course of the production procedure. Recovery of these solvents from the procedure exhaust air is desirable both from economic and environmental elements. The concept underlying the Donau Carbon SUPERSORBON-Solvent Recovery Process is the adsorption of solvents on activated carbon and their subsequent desorption by methods of superheated steam or hot inert gas.

Solvent recovery - PROJEKTNAMEsms-vt-temp.de.w013e9a7.kasserver.com

The 7-Second Trick For How labs are improving solvent recovery with Ecodyst - Ecodyst

The solvent recovery procedure counts on high-quality triggered carbon grades with a healthy pore structure. While This Author -pores are crucial to solvent retention and hence, compliance with the recommended VOC emission limits, the gain access to pores in the macro- and meso-pore variety help with desorption of the solvents from the triggered carbon.